Successfully Transitioning From Idea to Prototype

Technology-based companies frequently encounter a series of challenges colloquially known as the “valley of death,” which is the period when startups develop ideas—some becoming patent-protected—that later fade away as the entrepreneurs are unable to find a contractor to build their prototype. An early-phase product model is critical to gaining investor support.

New York Tech’s Entrepreneurship and Technology Innovation Center (ETIC) helps companies and entrepreneurs struggling to build functional prototypes, writes Michael Nizich, Ph.D., director of the ETIC, in an article in CXOTech Magazine.

“At the ETIC, we help companies rocket over the valley effectively and affordably, regularly,” Nizich writes. “As a high technology prototyping center with the business acumen to help entrepreneurs meet their investor goals and requests, we’ve identified a few key factors to help entrepreneurs navigate the valley of death and transition into successful investor demos.”

The initial consideration is not to minimize the creation process—“this is a costly plunge into the valley of death that many entrepreneurs do not recover from.” Nizich suggests startups adopt a humble attitude as to how much work must be completed before their idea may come to fruition “and be prepared to see the whole project through regardless of what obstacles may present themselves along the way,” he notes.

The next consideration for entrepreneurs is to ensure their prototyping contractor understands both their business model and the market space they intend to enter. “If the contractor understands your goals and markets early in the process, then they can become a bigger part of the design process earlier, versus being just a tool to be called upon when needed,” he writes.

Finally, Nizich advises it is ideal for entrepreneurs to begin with the finished product in mind and work backwards. As prototyping companies are usually paid hourly, entrepreneurs will incur more costs if they are unsure of what their final product specs will look like. Considering elements such as look, weight, sound, and energy consumption will help to create a product specification more in line with the final version. “This can save you thousands of dollars and countless hours, days, or even weeks of design time and delays if you just think ahead a little.”

Read the full article.

More News

My Co-op Gig: Engineering Together

For their co-op, friends and electrical and computer engineering classmates Pavan Kanakkassery and Oscar Cruz traveled to Texas twice to electrify a 16-wheeler industrial rig.

My Co-op Gig: Alisha Karim

Alisha Karim describes her co-op at Northwell Health as a perfect fit, renewing her excitement for a future career in tech.

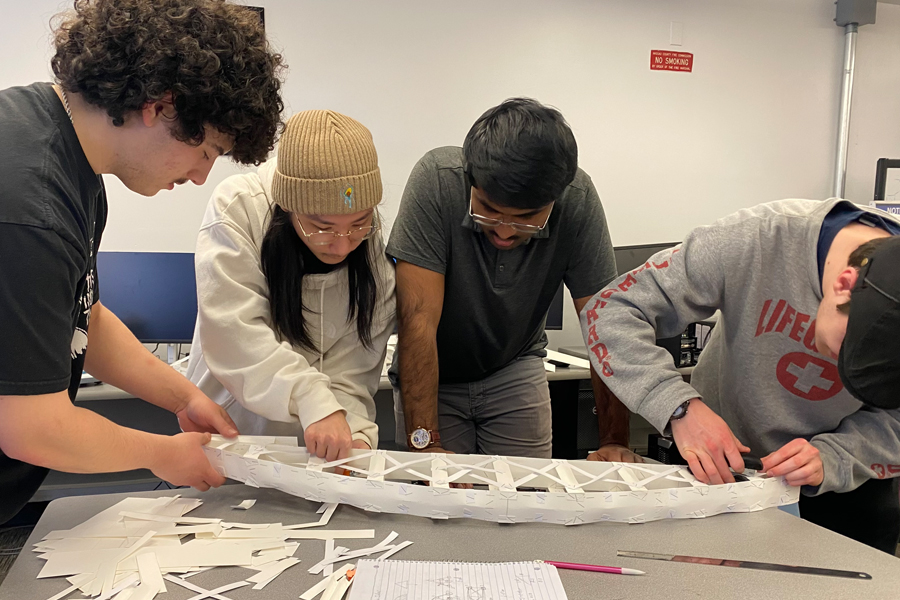

Building Bridges

New York Tech students earned first place at the 2026 KEEN Bridge Design Competition for their outstanding bridge design and structural efficiency.

Making an Impact

As an ETIC engineer, computer science student Angelina Do is working on a project in partnership with a former NBA star aimed to help children who stutter.

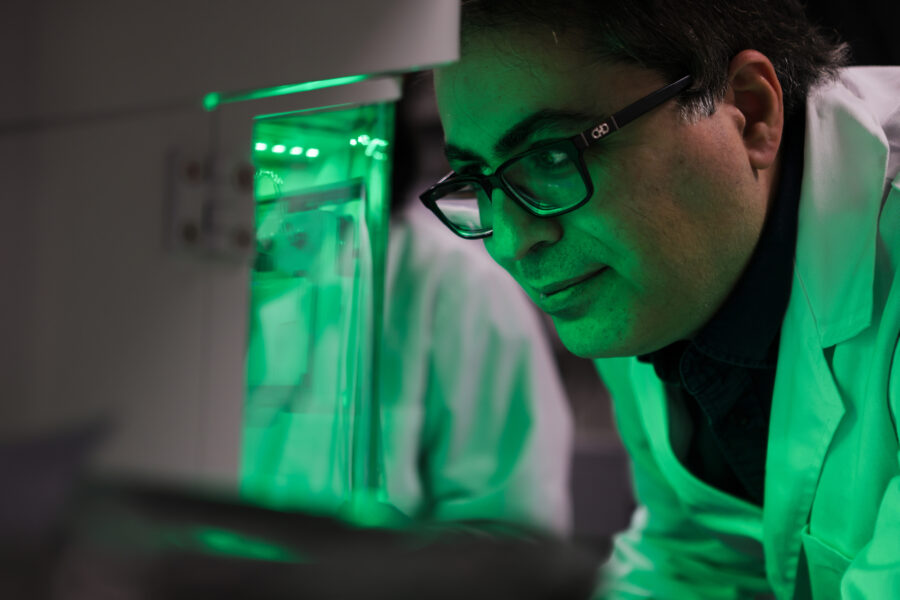

Realistic 3-D Colon Model Shifts Paradigm for Drug Development

Assistant Professor Steven Zanganeh, Ph.D., is striving to further improve the model he developed to open the door to drug development for cancer and other conditions.

Intentional Technology

Computer science student Tejas Attavar is putting his tech skills to altruistic use.